Integrating Instruments for Automated Sample Preparation and Nucleic Acid Extraction

Cristopher Cowan and Luke Roenneburg

Publication Date: 7/2018; tpub_200

Abstract

While the Maxwell® platform has addressed the low- to medium-throughput market, many laboratories desire higher throughput and/or automation of more of their nucleic acid extraction workflow. The introduction of the Maxprep® Liquid Handler is a perfect complement to the Maxwell® line of products. The Maxprep® Liquid Handler gives laboratories the flexibility to perform automated pre-processing for Maxwell® chemistries and post-processing activities to expand their workflow capabilities and throughput. In conjunction with the Maxwell® RSC or Maxwell® RSC 48 extraction instruments, the Maxprep® Liquid Handler offers a modular workflow for nucleic acid extraction and analysis. This modular workflow approach provides a flexible, easy solution for sample preparation, nucleic acid extraction and post-extraction analysis.

Introduction

Laboratories are encountering an increased demand for molecular testing and need workflow solutions that allow for greater automation and higher throughput, to keep up with the ever-increasing number of samples to be prepared for downstream applications such as PCR and NGS. Large integrated instruments have been available for several years but offer an inflexible workflow solution. These systems represent a significant investment for laboratories and typically require users to adapt their workflows to the capabilities and limitations of the instruments. Because these integrated systems automate entire workflows in the same instrument, when the instrument needs service, the entire workflow comes to a halt, even if only a portion of the instrument requires service. This can result in a backlog of samples, which puts strain on a laboratory’s ability to deliver results.

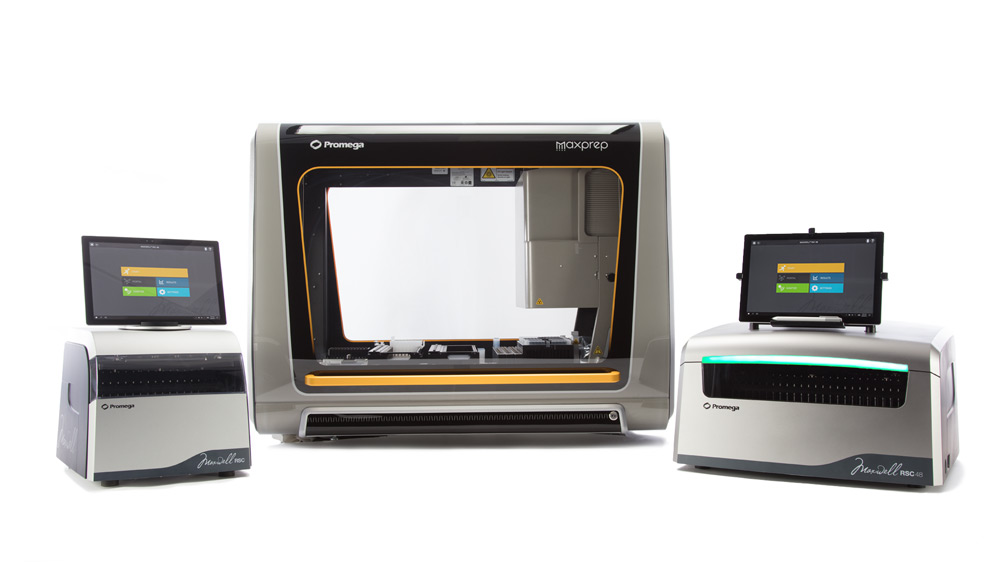

A modular approach to instrumentation ensures that if any individual instrument requires service, the workflow can continue. With a modular system it is possible to configure the system to meet the needs of the laboratory workflow. As laboratory needs continue to change and grow, it is possible to add modules into the workflow. We recently introduced a modular system that uses the Maxprep® Liquid Handler in conjunction with the Maxwell® RSC and Maxwell® RSC 48 nucleic extraction instruments. These instruments work together to provide a complete workflow for sample preparation, nucleic acid extraction and post analysis set-up, using downstream applications such as sample transfer, normalization and PCR setup. In addition, instrument modules can work in parallel allowing modules to perform pre-processing, extraction, or post-processing tasks simultaneously to boost efficiency. The instruments can be connected through the laboratory network using Promega Portal software to pass sample tracking information from one device to the next, maintaining sample chain of custody and providing users with guidance for the next steps in the sample workflow.

Automated Sample Preparation on the Maxprep® Liquid Handler

Automated sample preparation provides significant benefits to laboratories. It allows users to focus on more detailed work, while reducing the risk of exposure to chemicals and the need for repetitive motions, such as pipetting. Automated liquid handlers allow laboratories to handle increased sample processing demands while minimizing the need to increase headcount. While the promise of automation provides these benefits, many systems are complicated and intimidating for laboratory technicians to use and often sit idle in the laboratory. The Maxprep® Liquid Handler combined with the Maxwell® extraction instruments offer a turnkey solution for sample preparation.

The Maxprep® Liquid Handler uses Promega‐provided protocols for preparing samples prior to Maxwell® RSC extraction. The protocols are kit-specific and allow users the flexibility to adjust parameters within the Maxwell® RSC kit guidelines. The intuitive touchscreen software provide a visual and interactive interface for preparing the liquid handler worktable. Users can be trained and running samples within hours compared to the time involved in developing or purchasing complicated liquid handling protocols.

The Maxprep® Liquid Handler provides consistent and reproducible performance regardless of the operator. Automated bar code scanning of primary sample tube bar codes as they are loaded onto the system helps to ensure sample chain of custody. Promega Portal software tracks and monitors sample and reagent data from the point of sample scan and passes this information to the next instrument in the workflow such as extraction on the Maxwell® RSC and/or Maxwell® RSC 48 Instruments.

Performance is similar between samples prepared using the Maxprep® Liquid Handler and those prepared manually (Figure 1). The Maxprep® Liquid Handler provides sample preparation for Maxwell® RSC extraction chemistries, and consistent protocols for post-extraction processes, such as fluorescent dye‐based quantitation, normalization, sample transfers, dilutions, PCR, qPCR, RT‐PCR and RT‐qPCR. Initially launched with pre-processing protocols for ten Maxwell® RSC extraction kits, pre-processing methods for additional Maxwell® RSC kits will be available soon.

Figure 2. Dilution series of plasma samples spiked with 5 × 102 to 5 × 106 copies (n = 8) of lambda DNA per 300µl of sample. Samples were preprocessed using the Maxprep® Liquid Handler and extracted on the Maxwell® RSC 48 Instrument. Amplifications were set up using the Maxprep® Liquid Handler.

Figures 2 and 3 demonstrate results from a complete workflow using the Maxwell® RSC Viral Total Nucleic Acid Kit. Plasma samples were spiked with lambda phage DNA and dispensed into sample tubes. Pre-processing and Maxwell RSC® cartridge preparation was performed using a Maxprep® Liquid Handler. A Maxwell® RSC 48 Instrument extracted the lambda DNA. Finally, the eluted DNA was returned to the Maxprep® Liquid Handler for qPCR reaction setup using the GoTaq® Probe qPCR system. In Figure 2 the resulting quantitation data demonstrate the linearity of DNA extraction and qPCR performance across 4 logs of input DNA concentration. Figure 3 displays the resulting CT values of plasma samples each spiked with 5 x 106 copies of lambda phage DNA across 3 sequential runs.

Modular, Higher Throughput Nucleic Acid Extraction

The need for higher throughput extraction solutions is being driven by increased demand for molecular-based testing in areas such as oncology research. The Maxwell® RSC 48 Instrument is an extension of the Maxwell® RSC Instrument product line. This instrument provides the ability to extract 1 to 48 samples with the same performance (Figure 4) and in the same amount of time as the existing Maxwell® RSC platform. The system uses convenient prefilled cartridges and magnetic particles to extract nucleic acid from a wide variety of sample types.

Minimizing the potential for human error is also critical for laboratories. Instruments today need to be smarter and catch common mistakes that can lead to failed results and sample loss. The Maxwell® RSC 48 Instrument provides an integrated camera system that verifies instrument setup and provides specific details of any errors identified prior to initiating an extraction run.

Connectivity

Modularity in instrumentation workflow provides numerous advantages such as redundancy, expandability and adaptability. Multiple instruments that are intended to work as a cohesive unit must communicate with each other. The Promega Portal software is a database shared by each Promega module in the workflow. Each instrument can be connected through the laboratory’s network to pass information through Portal to the next module in the workflow.

Sample preparation performed on the Maxprep® Liquid Handler begins with scanning primary sample tube bar codes. When sample pre-processing is complete, Portal automatically makes this preparation information available to any connected Maxwell® RSC Instruments. Once extraction is completed on the Maxwell® RSC Instrument, Portal again passes the full set of sample information to the next instrument in the workflow. The Maxprep® Liquid Handler can access this information and use it to prepare samples for quantitation, import quantitation data for normalization and prepare samples for a variety of PCR reaction set-ups.

The Promega Portal allows the connected modules to work together through the laboratory network, acting as a single cohesive unit without the disadvantages associated with a large integrated instrument platform. The benefit of a modular instrument workflow is the inherent redundancy that is not possible with many of the less flexible large integrated-instrument platforms. If the Maxprep® Liquid Handler requires temporary service, the Maxwell® RSC chemistries can continue to be prepared manually in the short term. Multiple Maxwell® RSC Instruments can be incorporated into the workflow for redundancy in extraction, preventing any disruption in processing samples.

Summary

As laboratory needs change and evolve, the idea of a modular network of instruments working together as a seamless workflow becomes increasingly important. Instrumentation modules can be added to address aspects of the laboratory workflow that have increased throughput demands without having to acquire completely different platforms.

We are dedicated to continued development of the Maxprep® Liquid Handler and Maxwell® extraction instruments, with new methods currently in progress for each platform. The Maxwell® RSC and Maxprep® Systems will continue to expand and adapt, just as this modular automation system can continue to grow as your laboratory needs evolve.